CreaSolv® Pilot plant for post-consumer PVC floor coverings with banned Plasticizer

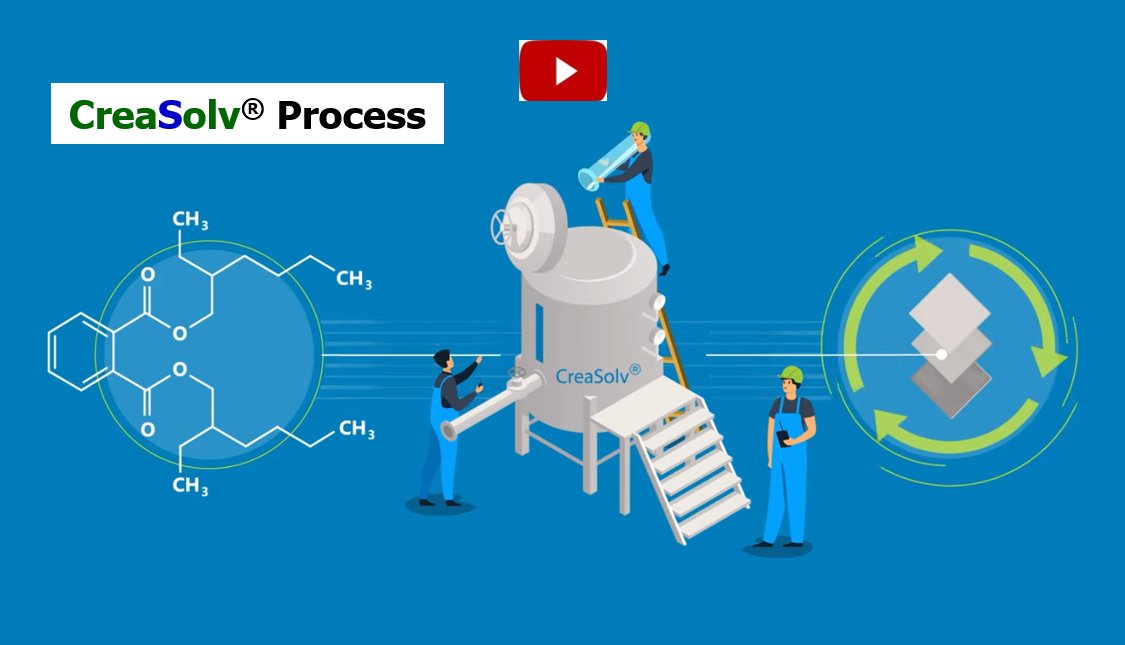

The overall aim of the project is to produce New Products from Waste PVC Flooring and Safe End-of-Life Treatment of Plasticisers, because only recycling rates of 20% have been achieved so far, while a large percentage of the PVC waste is still landfilled or incinerated. Therefore, the Circular Flooring consortium is further developing the CreaSolv® Process to separate the PVC (polyvinylchlorid) polymer from post-consumer floor coverings from legacy plasticizers (phthalic acid esters) that are not conform to the EU REACH-Directive.1)

The CreaSolv® Technology for PVC has already proven its viability in the lab. As part of the Circular Flooring Project, the technical and commercial feasibility for recycling of post-consumer PVC waste will now be demonstrated on a larger scale.

The extracted "legacy" phthalic acid esters like DBP, DIBP, BBP and DEHP will subsequently be deactivated by catalytic hydrogenation. The recovered PVC will then be further upgraded with tailored additives before it will be reused in new floor coverings and re-enter the market. Led by the Fraunhofer Institute IVV, the Circular Flooring consortium consist of 11 companies and research institutions. It receives funding of € 5.4 million from the EU Horizon 2020 program and will run from June 2019 until May 2023.

Led by the Fraunhofer Institute IVV, the Circular Flooring consortium consist of 11 companies and research institutions. It receives funding of € 5.4 million from the EU Horizon 2020 program and will run from June 2019 until May 2023.

This Circular Flooring project continues where the Vinyloop® Technology6) ended after 16 years successful operation, because it was not designed to remove banned plasticizers such as DEHP. The Vinyloop® plant (capacity: 10.000t/year) was designed for recycling PVC cables, recovered copper as by-product and later also PVC coated PET fibers were recovered (Texyloop®). It was in operation from 2002 to 2018. Vinyloop® was an important part of VinylPlus7), the voluntary commitment to sustainable development of the European PVC industry.

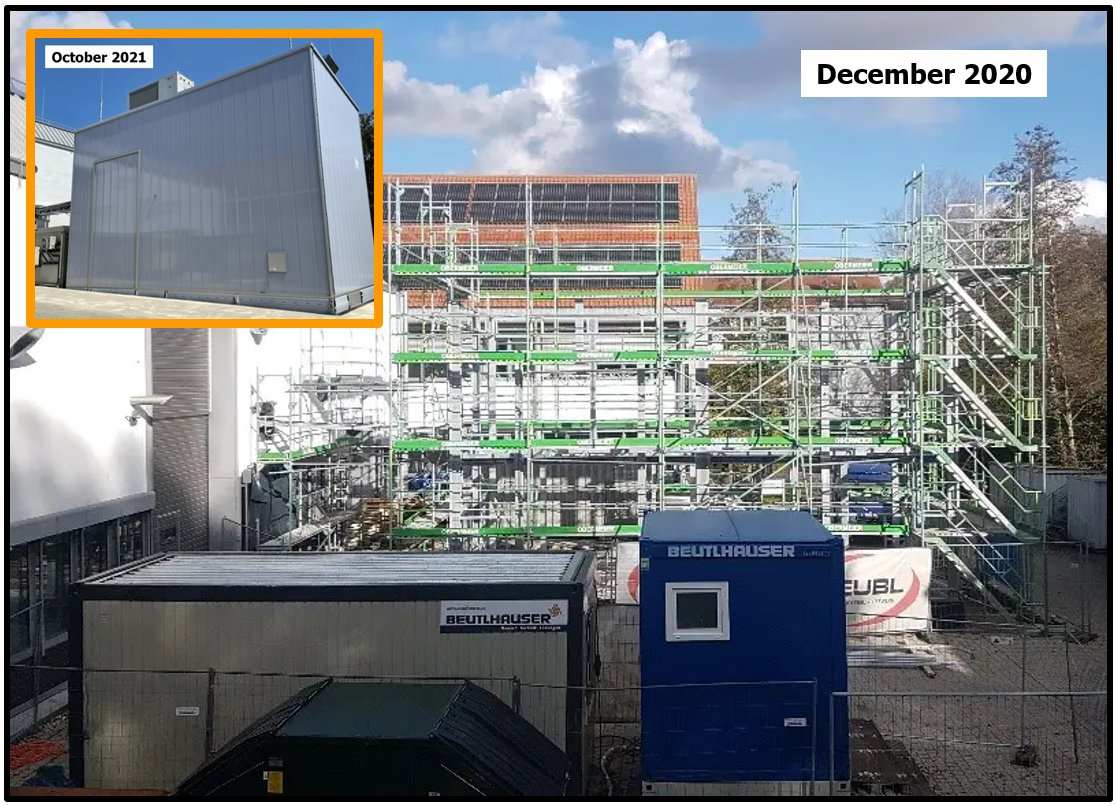

As part of the Circular Flooring project, a new CreaSolv® PVC Prototype recycling plant is being built on the premises of the Fraunhofer Institute IVV in Freising, Germany. This plant is funded by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy, the Fraunhofer IVV and by the European Union’s Horizon 2020 research and innovation programme. The construction of the surrounding building has begun in September 2020.2)

As part of the Circular Flooring project, a new CreaSolv® PVC Prototype recycling plant is being built on the premises of the Fraunhofer Institute IVV in Freising, Germany. This plant is funded by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy, the Fraunhofer IVV and by the European Union’s Horizon 2020 research and innovation programme. The construction of the surrounding building has begun in September 2020.2)

The plant is considered to reach a capacity of 15-20 kg/h and is intended to be used batch-wise rather than on a 24/7 utilization. It includes a dissolution unit for PVC waste, a filtration unit for the polymer solution, a batch or semi-continuous extraction unit and a unit specified for separation of PVC from solvents as well as a drying unit for PVC recyclate. The CreaSolv® Process makes use of safe solvents, tailor-made for safe industrial operations.

October 2021 - The facade, doors and gates were finished and the construction scaffolding could be removed. Also, the installation of the air conditioning on the roof of the building has taken place. The building has a height of 7,8 m and has a base area of 12,3 x 6,3 m. Over half the length of the hall, a gallery level will be drawn in at a height of 3 m so that the higher units can be better accessed from above. Inside the building, the crane and the scaffolding for the gallery has already been built-in and preparations for further indoor installations are made.3)

October 2021 - The facade, doors and gates were finished and the construction scaffolding could be removed. Also, the installation of the air conditioning on the roof of the building has taken place. The building has a height of 7,8 m and has a base area of 12,3 x 6,3 m. Over half the length of the hall, a gallery level will be drawn in at a height of 3 m so that the higher units can be better accessed from above. Inside the building, the crane and the scaffolding for the gallery has already been built-in and preparations for further indoor installations are made.3)

November 2022 – The new technical facility at Fraunhofer IVV is in the commissioning phase, ready for routine research operation in 2023.

November 2022 – The new technical facility at Fraunhofer IVV is in the commissioning phase, ready for routine research operation in 2023.

- > 100 m2 explosion proof area on 2 floors with modern equipment

- External process control

- Production capacity: >50 kg per day

- TRL 5-6

November 2023 – the large-scale technical centre for the recycling of solvent-based plastics was opened at Fraunhofer IVV. It is currently being used in the EU Circular Flooring project to recycle soft flooring and produce a plasticiser-free PVC recyclate.

4 July 2024 - Circular Flooring presented project’s key findings and results at its Final Conference in Brussels. After 5 years research, it has been proven

- that it is possible to produce plasticiser-free PVC recyclates from end-of-life flexible floor coverings with the CreaSolv® Process, that can efficiently remove critical legacy plasticisers from waste PVC flooring.

- that the recovered PVC complies with EU REACH legislation and can therefore be used to produce new PVC flooring. The project thus supports the EU objective of establishing a European circular economy.

- the technical feasibility of the process on a pilot scale, paving the way for scaling up to commercial dimensions.

“The aim of the Circular Flooring Project was, to find out, how to use the CreaSolv® Process at industrial scale.”

The Circular Flooring consortium met this challenge by developing a recycling process that offers the possibility to separate PVC from undesirable legacy plasticizers and therewith to recycle PVC for future production of floor coverings. At the same time, the separated plasticizers are transformed into uncritical plasticizers that are compliant with EU legislation and meet consumer needs with regard to circular economy. Link to project video 2.

Publications:

- Wagner, S., Schlummer, M. ‘Application of solvent-based dissolution for the recycling of polyvinylchloride flooring waste containing restricted phthalate plasticizers’, Resources, Conservation and Recycling, vol.211 - Link

- Windels, S., Nienke, S., Wouter, S., De Vos, D. (2024) ‚Catalytic revalorization of plastic waste phthalate plasticizers into simple aromatics and alkenes’, Front. Chem. Eng., vol.6 - Link

- Diefenhardt, T. Schlummer, M. (2023) ‘A step towards CIRCULAR FLOORING’, EU Research, Spring 2023 vol. (34) - Link

- Wagner. & M. Schlummer (2020): Legacy additives in a circular economy of plastics: Current dilemma, policy analysis, and emerging countermeasures. Resources, Conservation and Recycling. (158) 2020. - Link

- S. Windels; T. Diefenhardt; N. Jain; C. Marquez; S. Bals; M. Schlummer & D.E. De Vos (2022): Catalytic upcycling of PVC waste-derived phthalate esters into safe, hydrogenated plasticizers. Green Chem (24) 754-766 - Link

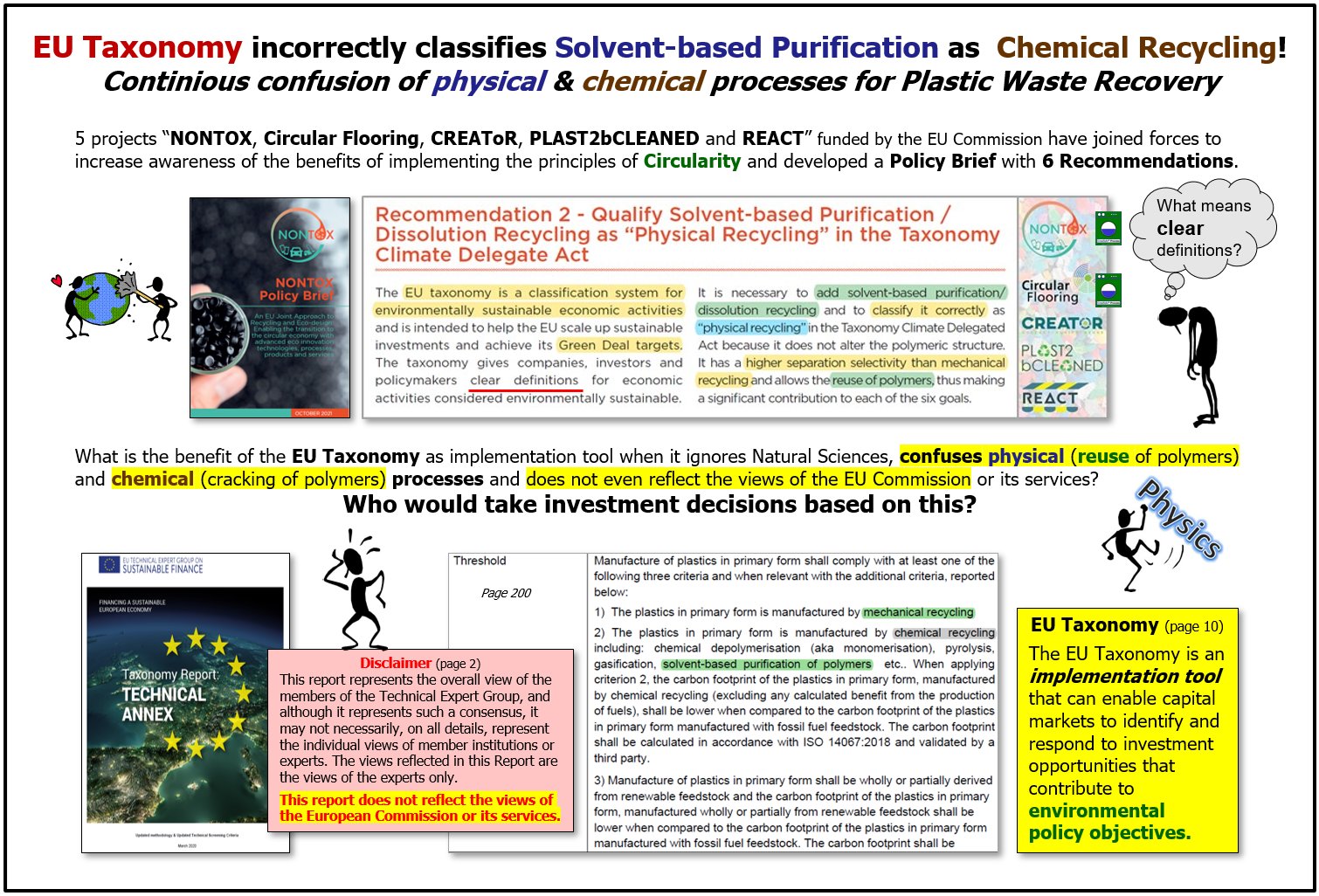

NONTOX Policy Brief

October 2021 - With a common focus on recycling and eco-design, 5 projects funded by the European Commission “NONTOX, Circular Flooring, CREAToR, PLAST2bCLEANED and REACT” have joined forces to increase awareness of the benefits of implementing the principles of circularity and developed the NONTOX Policy Brief with 6 recommendations.

Through their research, this project group is driving eco-innovation to enable recycling efficiency and closing the loop on the RE-USE of plastic materials in Europe….and struggle (as many others) about the permanent confusion of physical and chemical processes, expressed in Recommendation number 2: Qualify Solvent-based Purification / Dissolution Recycling as “Physical Recycling” in the Taxonomy Climate Delegate Act and not as chemical recycling as it is actually incorrectly classified.

Through their research, this project group is driving eco-innovation to enable recycling efficiency and closing the loop on the RE-USE of plastic materials in Europe….and struggle (as many others) about the permanent confusion of physical and chemical processes, expressed in Recommendation number 2: Qualify Solvent-based Purification / Dissolution Recycling as “Physical Recycling” in the Taxonomy Climate Delegate Act and not as chemical recycling as it is actually incorrectly classified.

NONTOX also works with the CreaSolv® Process -> Link

Circular Flooring Homepage - Link

Circular Flooring Project Video 1 – Link

Circular Flooring Project Video 2 - Link

- Circular Flooring Flyer – 18 February 2021 – Link

- Circular Flooring Rollup – 18. Februar 2021 – Link

- NONTOX Policy Brief – 07 October 2021 - Link

- Eco-innovation: Enabling the transition towards a green economy and society – 22 June 2021 – Link

Header photo: Circular Flooring project

Literature

- Circular Flooring News “Construction of the CreaSolv® PVC prototype recycling plants has started” posted 11 December 2020 – Link

- Circular Flooring News “Update on construction progress of CreaSolv® PVC prototype recycling plant” posted 11 October 2021 – Link

- Wikipedia "Vinyloop" - Link

- VinylPlus "Recycling" Homepage - Link