The Kick-off!

In 2001 Fraunhofer IVV made a feasibility study for the CreaCycle GmbH and Heger GmbH for solvent-based Recycling of EPS waste with the aim to test an alternative to the traditional „shredder – compress – re-extrude“ approach, because the latter has problems with impurities and additives.

The trigger for this study was the basic idea, that it will not be possible to collect diluted EPS waste in order to reduce the volume (and transportation cost), without a recycling process for this delivery form, that can use this „raw-material“ and offers advantages over mechanical recycling on top.

CreaCycle as a solvent formulation startup was interested in replacing traditional dangerous and often toxic solvents for solvent-based recycling processes by CreaSolv® Formulations, which will not only dissolve a target polymer in an optimum way, but also offers the lowest risk possible for users and environment and are ideally not classified (if this is technically probably.

Heger already began producing waste grinders for EPS waste in 1963 and since then, the company has continuously developed new systems for the rapidly growing recycling industry and brought in the know-how from this end.

IVV had know-how in respect to „selective extraction“.

As typical post-consumer EPS waste three qualities were tested:

1. Clean and not compacted

2. Clean and thermally compacted

3. Used fish-boxes with strong odor thermally compacted

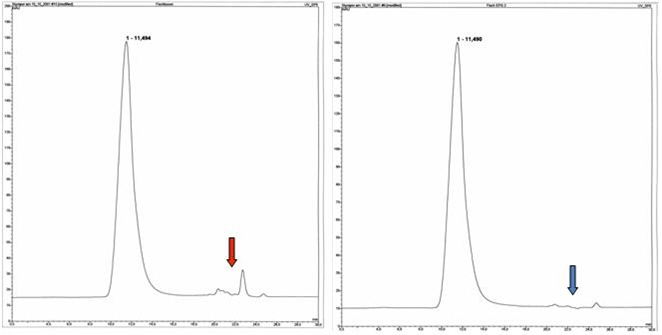

The Headspace-GC analysis showed that the polymer chains were still in tact after the recycling process and showed the original polymer quality. The cleaning efficiency in the case of the fish-boxes was 99,8%.

The Headspace-GC analysis showed that the polymer chains were still in tact after the recycling process and showed the original polymer quality. The cleaning efficiency in the case of the fish-boxes was 99,8%.

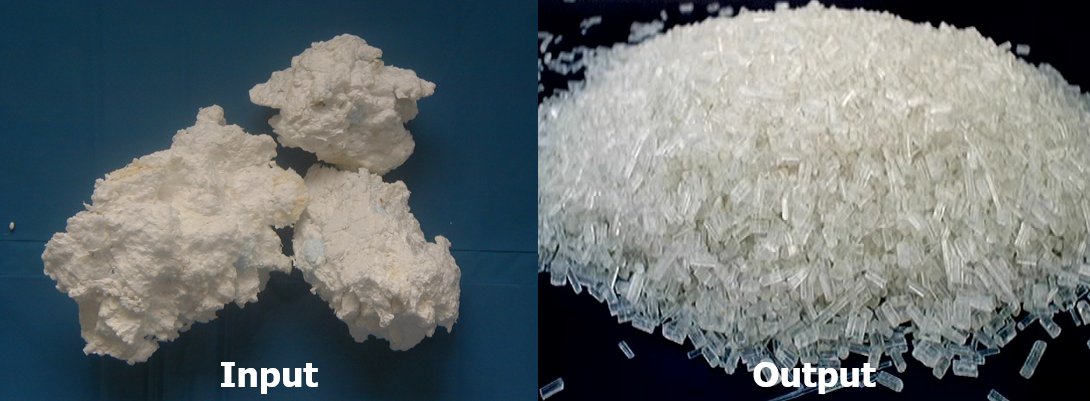

With this result it was proven, that via “dissolve – separate impurities – precipitate – dry” an effective separation of impurities in EPS is possible without decline of the polymer properties of polystyrene. In this study a non-classified CreaSolv® Formulation was used that is not considered as VOC in the EU VOC (Directive 1999/13/EC).