Polymers from flame-retarded Electro(nic) Waste / Environmental Impact Assessment

In a worldwide comparison study of the British non-profit-organisation WRAP (The Waste and Resources Action Programme), that lasted from 1 October 2004 until 31 May 2006, the CreaSolv® Process performed ecologically and economically as the best one. This finding was supported by a comprehensive Environmental Impact Assessment according ISO 14040 (Appendix 5 of WRAP Final Report).

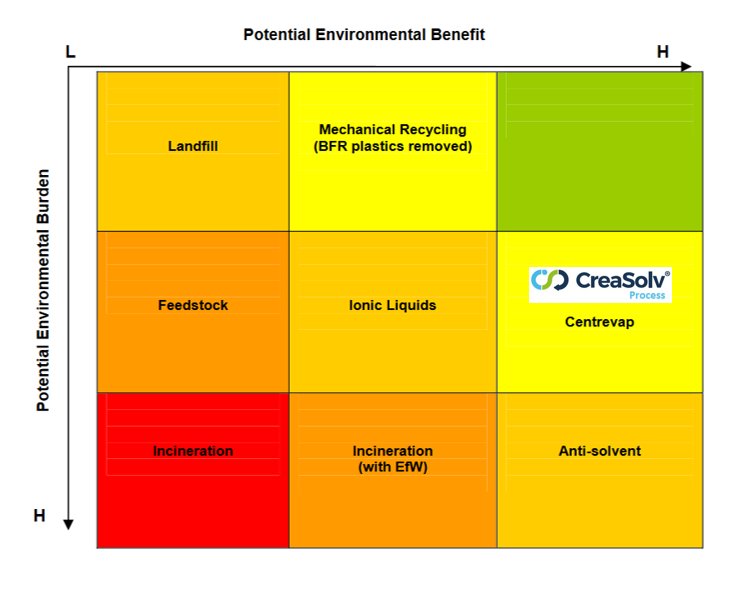

The qualitative assessment (page 158) identified the CreaSolv® Process, mechanical recycling with BFR separation and Centrevap process options as combining the lowest environmental burden with the best environmental gain.

In terms of primary energy consumption and global warming potential the CreaSolv® Process, Centrevap and mechanical recycling with BFR separation appear to provide the best net environmental gain because they avoid the substantial environmental impact of production of a significant quantity of high-grade polymer.

The CreaSolv® Process will remove most BFRs (brominated flame retardants) efficiently from most styrenic polymers found in WEEE, when Centrevap and mechanical recycling fail on this.

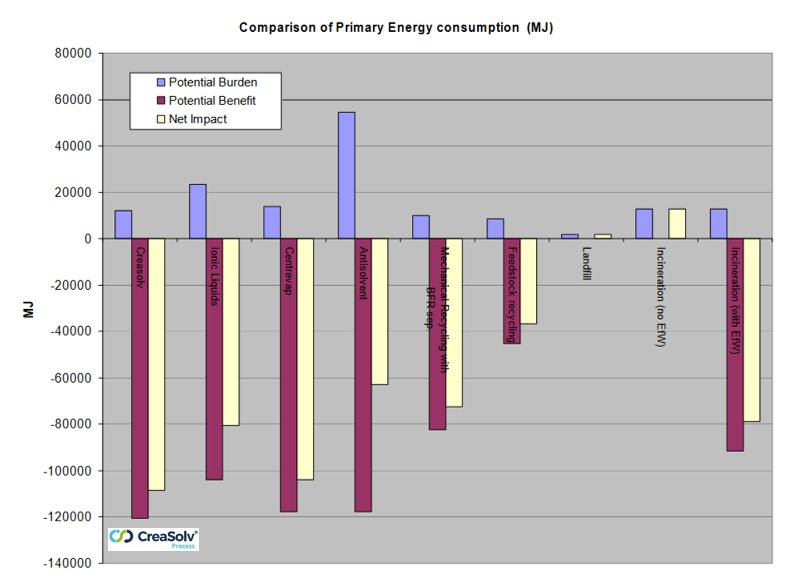

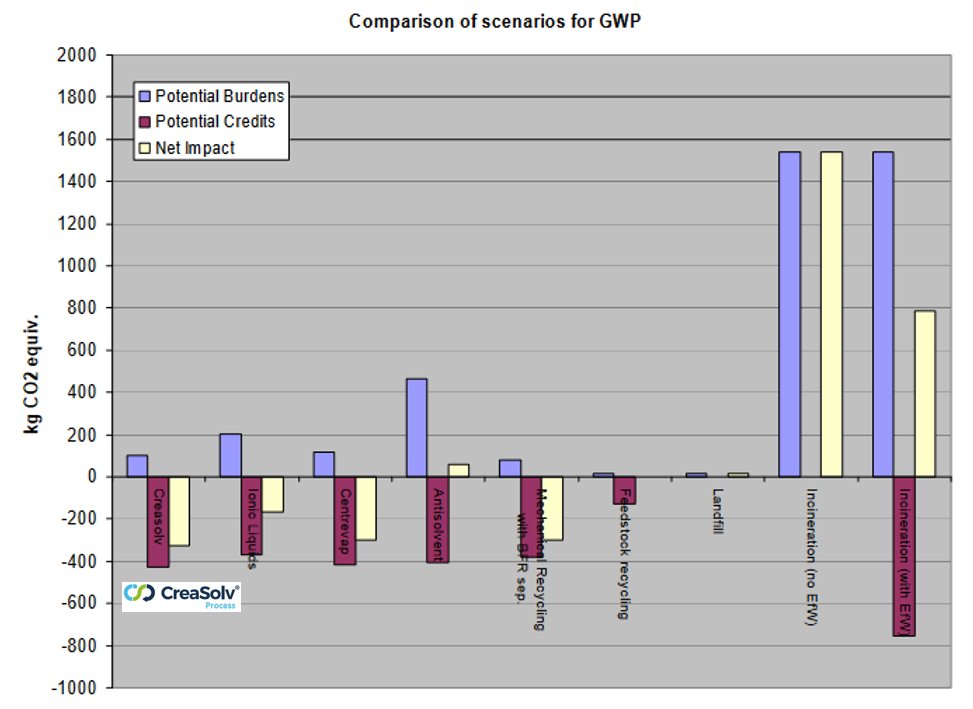

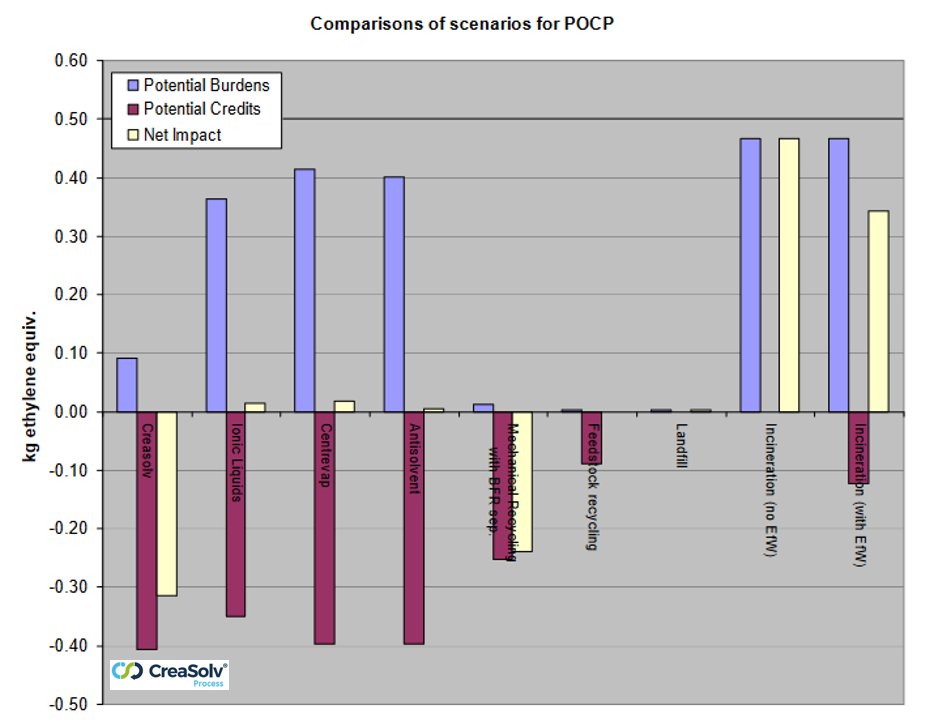

The quantitative analysis measured the environmental burdens and gains of the process options for three representative impact categories:

- Primary energy consumption (PE)

- Global Warming potential (GWP)

- Photochemical oxidation potential (POCP)

In terms of primary energy consumption and global warming potential the Creasolv® Process, Centrevap and mechanical recycling with BFR separation appear to provide the best net environmental gain because they avoid the substantial environmental impact of production of a significant quantity of high-grade polymer.

In terms of primary energy consumption, the environmental burden of these recovery processes (including transport of the materials from point of collection to point of treatment) is less than 20% of the burden of the virgin polymer production process, even when the yield of the recovery process is taken into account.

Centrevap is estimated to be less attractive than the Creasolv® Process and mechanical recycling in terms of photochemical oxidation potential because it has potential for greater emissions of volatile solvents.

A summary of the Impact Assessment can be found in the WRAP Final Report on page 157.

WRAP was looking for technologies to separate brominated flame retardants from plastics of old electro(nic) equipment, because such a technology did not exist and in order to cope with the waste-avoiding-strategy of the British Government .

The report recommends the CreaSolv® Process for the treatment of styrenic WEEE polymers (HIPS, ABS) containing brominated flame retardants.

According to Axion, a British plastic recycling company, the UK currently recycles 10.000 – 15.000 tonnes of plastic waste per year, but will have to deal with around 30.000 tonnes when the WEEE directive kicks in. WRAP asked Axion to test out the most workable solutions for recovering polymers from e-waste and the concluded that the most cost-effective, safest and commercially viable option was the CreaSolv® Process1).

More information:

- IVV Press release on 18 August 2006 – Kunststoffe aus Elektro-/Elektronikschrott wirtschaftlich recyceln – link pdf

- November 2006 – WRAP Final Report: Develop a process to separate brominated flame retardants from WEEE polymers. – link pdf

- November 2006 – WRAP Final Report: Appendix 1 - 4. - link pdf

- November 2006 – WRAP Final Report: Appendix 5 - Detail of White Young Green and Huisman Environmental Impact Assessments. - link pdf

- RECYCLING magazin 17 – 2006 CreaSolv®-Verfahren Testsieger bei Recyclingvergleich – link pdf

- 20 April 2007 – Trial results reveal new extraction processes for additives will encourage WEEE plastics recycling - link pdf

- EU-Recycling 1.Jahrgang/Volume ePaper-Ausgabe/Edition 6/2007: CreaSolv® und Centrevap: WRAP testete Methoden zur Additiv-Separation bei WEEE-Kunststoffen – link pdf

- Kunststoffe 12/2008 - Das ist die "Lösung"! / That's the "Solution"! - link pdf

- Chemistry World, June 2007 „The gadget scrap heap“ p.44-48 – link pdf